Nanocrystalline Toroidals Cores

Fe-Based Nanocrystalline Toroidals Cores

APPLICATIONS

BENEFITS

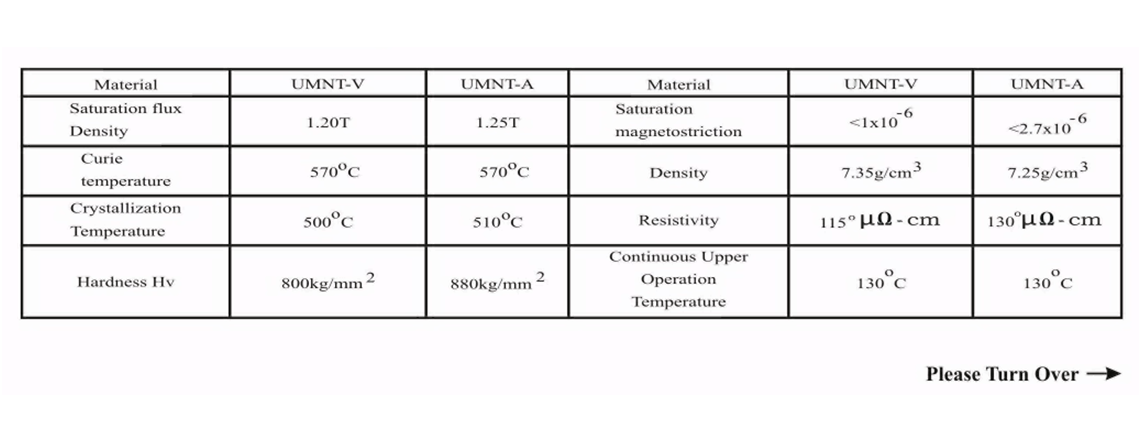

PHYSICAL & MAGNETIC PROPERTIES

TECHNICAL SPECIFICATIONS

PRODUCT CATALOGUE

APPLICATIONS

- Common made chokes used in EMC/EMI Filter far SMPS and inverter drives

- Transformer Cores for high frequency Switched mode power supplies

- Electrical welding power sources

- X- ray generators

- Battery charger

- Solar generators

- Sensor cores

- AC-to-DC & DC-to-DC converters

- Cores Used in Power supplies in the automotive industry

- Cores for saturable reactors, magnetic amplifiers, beads, and pulse compressors

- Railways Transportation Systems

- Electronic Watt-Hour Meters

- Transformer Cores for Earth Leakage circuit breakers (ground fault interrupters).

BENEFITS

- Significantly smaller build volume (up to more than a factor of 3)

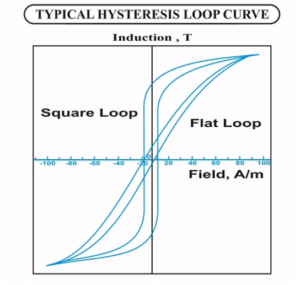

- Satisfy both high saturation magnetic flu density and high permeability long with low coertivity.

- Makes the single stage filter designs possible.

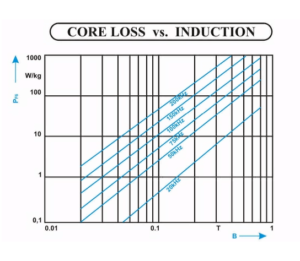

- Low core loss (approximately 1/5th of the Fe based amorphous metal).

- Low magnetostriction, thus less affected by mechanical stress.

- Low number of turns required for high L, thus reducing number of filter stages.

- High ffcency hence low power loss and hence less use of material makesit eco friendly

- Very low audible Noise emission.

- Less copper loss due to reduced number of turns.

- Aging effects are very small unlike Co-based amorphous metals.

- Epoxy coated fiber glass tape/casing is resistant against mechanical stress.

- Excellent high frequency characterises as the value of permeabilities and core losses remain high and low respectively at very wide range of frequencies.

- Extended temperature range from -25°C…..+ 120°C (Standard) / 180°C (Special) due to high Curie temperature, thus making material properties nearly independent of temperature.

PHYSICAL & MAGNETIC PROPERTIES

TECHNICAL SPECIFICATIONS

PRODUCT CATALOGUE

| PRODUCT MADE BY CHINA MATERIAL | |||||||||||

| PART No. | Bare dimensions (mm) | With Reinforcement dimensions (mm) | Im* (cm) | Ae* (cm²) | Wa* cm² | Mfe* (g) | AL (μH)±30% 10kHz | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | ID | Height | OD | ID | Height | ||||||

| UMNT-A0131005 | 12.5 | 9.5 | 5.0 | 14.5 | 7.5 | 6.8 | 3.46 | 0.06 | 0.71 | 1.4 | 3.11 |

| UMNT-A0201308 | 20.1 | 12.7 | 8.0 | 22.0 | 10.7 | 9.8 | 5.14 | 0.22 | 1.27 | 8.3 | 8.14 |

| UMNT-A0201310 | 20.1 | 12.7 | 10.0 | 22.5 | 10.2 | 12.3 | 5.14 | 0.28 | 1.27 | 10.3 | 10.18 |

| UMNT-A0261910 | 25.6 | 19.1 | 10.0 | 28.1 | 16.6 | 12.3 | 7.02 | 0.25 | 2.87 | 14.6 | 6.63 |

| UMNT-A0252015 | 25.0 | 20.0 | 15.0 | 27.6 | 15.0 | 17.0 | 7.6 | 0.28 | 2.87 | 17.4 | 7.6 |

| UMNT-A0302010 | 30.0 | 20.0 | 10.0 | 33.0 | 17.2 | 12.4 | 7.85 | 0.28 | 3.14 | 21.6 | 9.12 |

| UMNT-A0402520 | 40.0 | 25.0 | 20.0 | 43.0 | 21.4 | 23.2 | 10.21 | 1.14 | 4.91 | 41.9 | 21.05 |

| UMNT-A0504020 | 50.0 | 40.0 | 25.0 | 53.4 | 36.6 | 23.7 | 14.14 | 1.79 | 7.92 | 77.9 | 10.13 |

| UMNT-A0645025 | 64.0 | 50.0 | 25.0 | 67.4 | 46.6 | 33.2 | 19.63 | 1.33 | 19.63 | 193.3 | 12.76 |

| UMNT-A0645030 | 64.0 | 50.0 | 30.0 | 67.4 | 46.6 | 33.2 | 19.63 | 1.9 | 19.63 | 207.2 | 13.44 |

| UMNT-A0755030 | 75.0 | 55.0 | 30.0 | 78.4 | 48.6 | 33.2 | 25.88 | 2.66 | 29.45 | 405.7 | 18.89 |

| UMNT-A0805030 | 80.0 | 60.0 | 30.0 | 83.4 | 48.6 | 33.2 | 20.42 | 3.42 | 32.47 | 506.3 | 19.65 |

| UMNT-A0906030 | 90.0 | 60.0 | 30.0 | 93.4 | 56.6 | 33.2 | 23.56 | 3.87 | 37.94 | 584.2 | 21.89 |

| UMNT-A1008030 | 100.0 | 80.0 | 30.0 | 103.4 | 76.6 | 33.2 | 28.27 | 2.28 | 50.27 | 467.4 | 12.16 |

| PRODUCT MADE BY VAC MATERIAL | |||||||||||

| PART No. | Bare dimensions (mm) | With Reinforcement dimensions (mm) | Im* (cm) | Ac* (cm²) | Wa² (cm²) | Mfe* (g) | AL (μH)± 30% 10kHz | ||||

| OD | ID | Height | OD | ID | Height | ||||||

| UMNT-V0131005 | 12.5 | 9.5 | 5.0 | 14.5 | 7.5 | 6.8 | 3.46 | 0.06 | 0.15 | 1.5 | 9.3 |

| UMNT-V0201308 | 20.0 | 12.0 | 8.0 | 22.0 | 10.7 | 9.8 | 5.14 | 0.22 | 1.27 | 8.4 | 24.43 |

| UMNT-V0201310 | 20.0 | 12.7 | 10.0 | 22.0 | 10.8 | 9.8 | 5.14 | 0.22 | 1.27 | 8.4 | 30.54 |

| UMNT-V0261910 | 25.6 | 19.1 | 10.0 | 28.0 | 16.6 | 10.8 | 7.02 | 0.25 | 2.87 | 12.8 | 19.89 |

| UMNT-V0252015 | 25.0 | 20.0 | 15.0 | 28.0 | 16.0 | 15.0 | 7.02 | 0.29 | 2.87 | 14.3 | 32.97 |

| UMNT-V0251620 | 25.0 | 16.0 | 20.0 | 28.0 | 13.2 | 22.3 | 6.44 | 0.68 | 5.03 | 20.1 | 60.06 |

| UMNT-V0252020 | 25.0 | 20.0 | 20.0 | 28.0 | 13.2 | 22.8 | 6.44 | 0.71 | 5.03 | 20.3 | 50.64 |

| UMNT-V0302010 | 30.0 | 20.0 | 10.0 | 33.0 | 21.6 | 12.3 | 7.85 | 0.38 | 4.14 | 12.1 | 27.36 |

| UMNT-V0402520 | 40.0 | 25.0 | 20.0 | 43.0 | 26.2 | 21.0 | 11.32 | 0.94 | 8.42 | 25.2 | 37.81 |

| UMNT-V0504020 | 50.0 | 40.0 | 20.0 | 53.4 | 40.0 | 22.8 | 14.14 | 1.25 | 12.57 | 59.9 | 40.4 |

| UMNT-V0504025 | 50.0 | 40.0 | 25.0 | 53.4 | 40.0 | 23.0 | 14.14 | 1.25 | 12.57 | 70.4 | 58.33 |

| UMNT-V0645025 | 64.0 | 50.0 | 25.0 | 67.4 | 50.0 | 22.8 | 17.91 | 1.91 | 15.15 | 111.5 | 25.83 |

| UMNT-V0645030 | 64.0 | 45.0 | 30.0 | 67.4 | 50.0 | 22.8 | 17.91 | 1.91 | 15.15 | 125.3 | 33.1 |

| UMNT-V0755030 | 75.0 | 50.0 | 30.0 | 78.4 | 60.0 | 23.2 | 21.83 | 2.26 | 18.84 | 193.5 | 40.44 |

| UMNT-V0805030 | 80.0 | 50.0 | 30.0 | 83.4 | 60.0 | 23.2 | 22.47 | 2.35 | 19.63 | 516.8 | 44.44 |

| UMNT-V0906030 | 90.0 | 60.0 | 30.0 | 93.4 | 60.0 | 23.2 | 23.56 | 3.42 | 28.27 | 596.3 | 45.69 |

| UMNT-V1008020 | 100.0 | 80.0 | 20.0 | 103.4 | 76.6 | 23.2 | 28.27 | 1.52 | 50.27 | 318.0 | 16.89 |

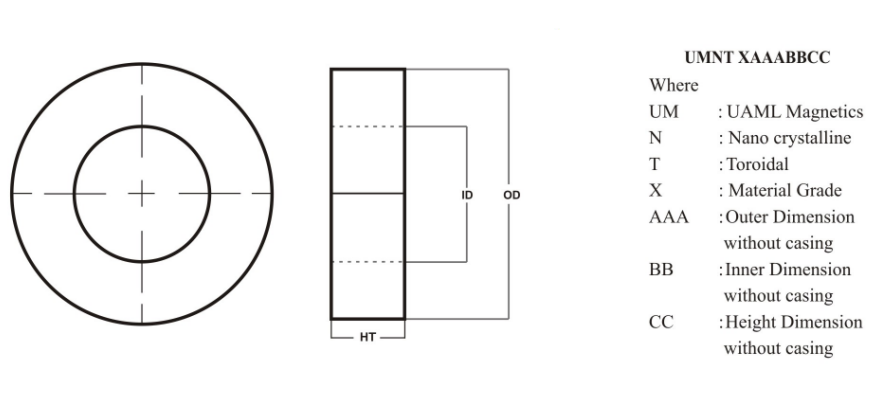

Product Identification