Amorphous E Core

Fe Based Amorphous E Cores

E-Cores are manufactured with both iron based amorphous alloy. Their unique combination of low loss and high saturation flux density take advanced power conditioning applications to higher performance levels than previously possible with conventional ferromagnetic materials.

APPLICATIONS

BENEFITS

PHYSICAL & MAGNETIC PROPERTIES

TECHNICAL SPECIFICATIONS

PRODUCT CATALOGUE

APPLICATIONS

- Transformer cores in SMPS

- Output filter cores in HF large power supplies

- Solar & Wind Power Supplies

- UPS Harmonic filter Inductor

BENEFITS

- High saturating flux density (1.56 T)

- Low profile enables weight and volume reduction upto 50%

- Low loss resulting from micro thin ribbon (25 micron)

- Low temperature rise – enabling compact design

- Excellent temperature stability

PHYSICAL & MAGNETIC PROPERTIES

- Ribbon Thickness (µm) ………………………………………………………………………………………………25

- Density (g/cm3)……………………………………………………………………………………………………………..7.19

- Thermal EXpansion (ppm/°C)……………………………………………………………………………………7.6

- Crystalline Temperature (°C)……………………………………………………………………………………..550

- Curie Temperature (°C)………………………………………………………………………………………………..415

- Continuous Service Temperature (°C)……………………………………………………………………155

- Tensile Strength (MN/m2)…………………………………………………………………………………………….1k-1.7k

- Elastic Modulus (MN/m2)……………………………………………………………………………………………..100-110

- Vickers’s Hardness (50g load)…………………………………………………………………………………..860

- Saturation Flux Density (Tesla)………………………………………………………………………………….1. 56T

- Permeability (depending on gap size)……………………………………………………………………Variable

- Saturation Magnetostriction (ppm)………………………………………………………………………..27

- Electrical Resistivity (µΩ_cm)…………………………………………………………………………………..137

TECHNICAL SPECIFICATIONS

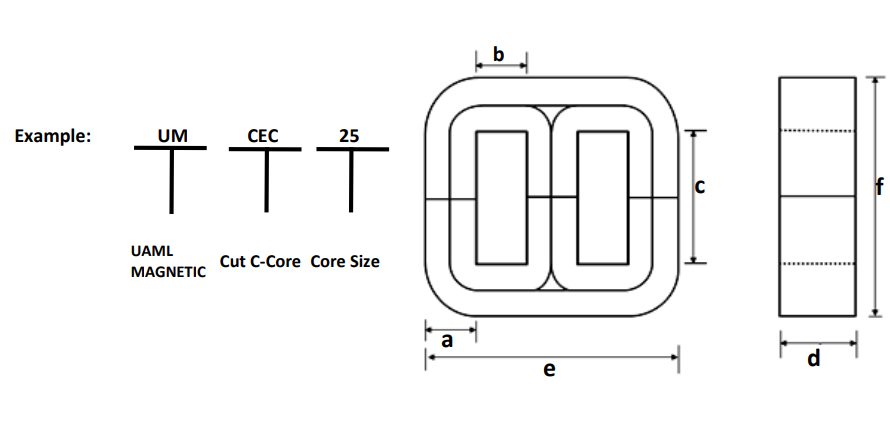

PRODUCT CATALOGUE

| CORE SIZE | a (mm) | b (mm) | c (mm) | d(mm) | e(mm) | f(mm) | Ac(cm2) | Wt. (gm) ±396% | Window Area(cm2) |

|---|---|---|---|---|---|---|---|---|---|

| UMCEC-7 | 14.5±0.5 | 15.75±0.5 | 11.5±1.0 | 15.0±0.5 | 75.1±1.5 | 40.5±1.5 | 1.8 | 227 | 3.6 |

| UMCEC-9 | 14.5±0.5 | 15.75±0.5 | 11.5±1.0 | 20.0±0.5 | 75.1±1.5 | 40.5±1.5 | 2.4 | 303 | 3.6 |

| UMCEC-11 | 12.5±0.5 | 13.0±0.5 | 41.5±1.0 | 20.0±0.5 | 63.5±1.5 | 66.5±1.5 | 2.1 | 365 | 5.4 |

| UMCEC-11A | 12.5±0.5 | 10.5±05 | 33.0±1.0 | 15.0±0.5 | 58.5±1.5 | 58.0±1.5 | 1.6 | 235 | 6.9 |

| UMCEC-25 | 14.5±0.5 | 15.75±0.5 | 30.0±1.0 | 20.0±0.5 | 69.0±1.5 | 59.0±1.5 | 2.38 | 387 | 9.45 |

| UMCEC-42 | 15.0±0.5 | 13.5±0.5 | 41.0±1.0 | 30.0±0.5 | 72.0±1.5 | 71.0±1.5 | 3.8 | 700 | 11.1 |

| UMCEC-58 | 15.0±0.5 | 20.5±0.5 | 56.0±1.0 | 20.0±0.5 | 85.0±2.0 | 86.0±2.0 | 2.6 | 605 | 22.4 |

| UMCEC-115 | 14.5±0.5 | 15.8±0.5 | 30.0±1.0 | 100.0±1.0 | 75.0±2.5 | 59.0±2.0 | 12.2 | 2022 | 9.5 |

| UMCEC-410 | 29±1.0 | 29.5±0.5 | 95.0±1.5 | 30.0±0.5 | 146.0±2.5 | 153.0±2.5 | 7.3 | 2950 | 56.1 |

| UMCEC-453 | 38±1.0 | 25.0±0.5 | 83.0+ .5 | 35.0±0.5 | 164.0±2.5 | 159.0±2.5 | 10. 91 | 4367 | 41.5 |

| UMCEC-640 | 40±1.0 | 30.0±1.0 | 155.0±2.0 | 20.0±0.5 | 180.0±2.5 | 235.0±3.0 | 6. 9 | 3979 | 93 |

| UMCEC-1103 | 38±1.0 | 37.0±1.0 | 114.0±2.0 | 40.0±1.0 | 188.0±2.5 | 190.0±3.0 | 13 | 6468 | 84.4 |

| UMCEC-1645 | 30±1.0 | 48.0±0.5 | 170.0±2.0 | 40.0±1.0 | 186.0±2.5 | 230.0±3.5 | 10.1 | 6276 | 163.2 |

| UMCEC-1904 | 44±1.5 | 43.0±1.0 | 130.0±2.0 | 45.0±1.0 | 218.0±2.5 | 218.0±3.5 | 17.0 | 9714 | 111.8 |

| UMCEC-2961 | 44±1.5 | 43.0±1.0 | 130.0±2.0 | 70.0±1.5 | 218.0±2.5 | 218.0±3.5 | 26.5 | 15224 | 111.8 |

| UMCEC-3032 | 48.0±1.5 | 51.0±1.5 | 144.0±1.0 | 50.0±1.5 | 246.0±3.5 | 240.0±3.5 | 20.64 | 13405 | 146.88 |

| UMCEC-4548 | 48.0± 1.5 | 51.0±1.5 | 144.0±1.0 | 75.0±1.5 | 246.0±3.5 | 240.0±3.5 | 30. 96 | 20105 | 146.88 |

| UMCEC-4926 | 48.0±1.5 | 51.0±1.5 | 156.0±2.0 | 75.0±1.5 | 246.0±3.5 | 252.0±3.5 | 31.0 | 20719 | 159.1 |

| UMCEC-6063 | 48.0+1.5 | 51.0±1.5 | 144.0±1.5 | 100.0±1.5 | 246.0±3.5 | 240.0±3.5 | 41.28 | 26806 | 146.88 |

| UMCEC-6224 | 16.5±1.0 | 33.0±1.0 | 60.0±1.0 | 85.0±1.0 | 186.0±3.0 | 249.7±3.5 | 24.12 | 11200 | 258 |

| UMCEC-6913 | 55.0+1.5 | 56.0±1.5 | 145.0±1.5 | 90.0±1.5 | 277.0±3.5 | 255.0±3.5 | 42.57 | 29509 | 162.4 |

| UMCEC-12200 | 55.0±1.5 | 56.0±1.5 | 277.0±2.0 | 85.0±1.5 | 277.0±3.5 | 387.0±4.0 | 39.3 | 38335 | 310.2 |

Product Identification